Some Known Incorrect Statements About Digital Printing

Some Known Incorrect Statements About Digital Printing

Blog Article

An Unbiased View of Digital Printing

Table of ContentsUnknown Facts About Digital PrintingThe smart Trick of Digital Printing That Nobody is DiscussingDigital Printing Fundamentals Explained

Digital printing additionally calls for minimal setup. Here are the key means in which electronic printing sustains greener techniques: One of the considerable ecological benefits of electronic printing is minimizing waste (Digital Printing). Typical printing methods, like lithographic printing, commonly waste substantial amounts of paper and ink during the setup stage.

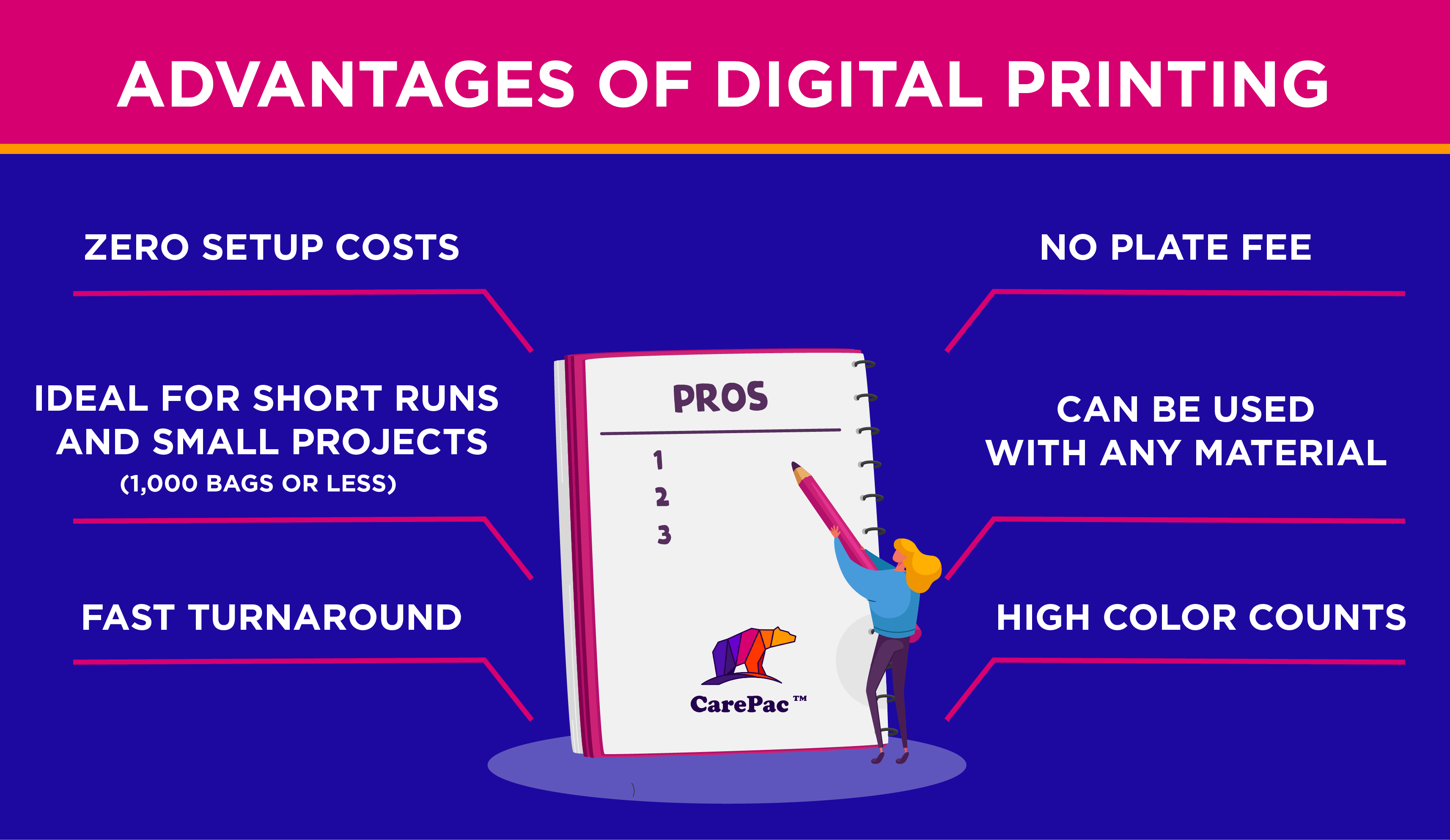

Digital printing machine get rid of the need for these plates, dramatically lowering arrangement costs. Digital printing presses can integrate variable information right into your prints, which enables highly personalized advertising materials (Digital Printing). By customizing your advertising materials, you can enhance interaction with potential consumers and enhance the chances of converting them into actual clients

In electronic printing, there are 2 various printing modern technologies to pick from: check printing and single-pass printing. As a reasonably brand-new printing innovation, Single-pass printing can not just enhance printing speed, however also enhance publishing top quality, however, this requires even more nozzles to be mounted on the printing machine. Business owners who have actually made use of electronic inkjet printing machines know that fabric electronic printing is completed generally by the printheads and Homepage printing inks.

Printers have to make use of a lot more fluid inks to stop nozzle blocking and printhead failing. In order to avoid rust of the nozzle, the ink for digital printing is much more costly than the ink for conventional printing, and extra ink purification is needed during the printing procedure. In addition, the advantage of digital inkjet printing is apparent only when making use of inks with a huge shade range. The digital inkjet printing machine nearly realizes the automated control process. In electronic inkjet printing, the pattern is directly printed on the fabric, removing the plate making in rotary display printing. It not just saves the beneficial time of plate production, why not look here but additionally saves the additional price of plate making. At the very same time, an increasing number of brand names are now increasingly more accepting of paying greater costs for faster distribution, such as delivering a set of materials within a week and even 3 days, as opposed to weeks and months - Digital Printing. Yes, are more costly than conventional printing inks, yet the electronic printing process can conserve ink consumption.

Today, the digital direct-injection printing machine has actually gone from proofing to the phase of medium-sized and large-sized manufacturing. The electronic direct-injection device has actually undergone the promotion period and went into the development and maturation duration. Both printing homes and brand name proprietors understand the development capacity of electronic printing, and agree to raise investment in electronic printing. The print quality can often even rival that of offset printing. Digital printing is extra cost-effective for brief print runs since it requires much less pre-press activities and less setup than balanced out printing. If a mistake in countered printing is not caught before home plates are made, it will certainly be really costly to make new ones. While everybody seriously really hopes that mistakes will be prevented, it is practical to prepare for their prospective modification. In enhancement, its accuracy is extremely high. This makes sure harmony in look across the board, decreasing the probability that any type of piece will need to be thrown away due to defects. Making sure home plates remain in area, the ink key is calibrated, and all the necessary adjustments have been made is a lengthy process when countered printing. Decreased pre-press steps indicate much less time is required to establish the press additional hints initially. This causes a significant velocity of turnaround time. When you need printed products quickly, this is a great alternative. Digital printing can be a lifesaver when you obtain an order in the nick of time.

Variable information printing, such as straight mail with individualized codes and addresses, is preferably matched for electronic printing. Digital quick printing only needs 4 actions of design, review, printing and binding to get whatever done. Digital fast printing has an unequaled benefit: print on demand.

Report this page